03.03.2025

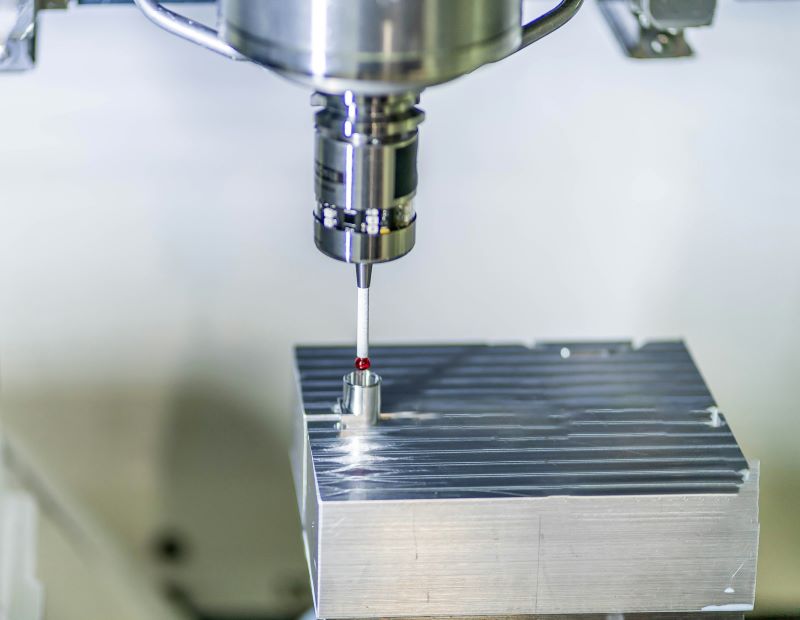

CNC milling of aluminum is a service that allows for effective processing of this material. The use of modern numerically controlled machines significantly improves its implementation. Shaping aluminum in this way is a very versatile solution, thanks to which it is possible to obtain various details. A significant advantage remains high repeatability and precision, which guarantees strict compliance with the target parameters.

What is CNC milling of aluminum?

CNC milling of aluminum is one of the solutions available in the offer of Karbo CNC, where we use many advanced and effective methods of processing this material. We are also able to perform other services, the list of which is on our website.

In the case of milling, the machining consists of immobilizing the workpiece and then processing it using the moving components of the cutting tool. We also perform this type of work on other metals and other materials.

Numerical control

CNC is an advanced technology based on computer numerical control. This solution involves the use of special algorithms and software functions to operate a milling machine. The saved commands from the program are then implemented by a controller integrated with the CNC machine.

The aluminum processing procedure in this form is almost completely automated, which significantly reduces the need for manual intervention. Our task is only to properly equip the machine, secure the material and call the planned program.

Karbo CNC specialists are trained professionals who approach each order professionally and creatively. We have a complete machine park, which allows us to provide full service – including the development of CAD/CAM projects and the delivery of final products.

Effective processing

Aluminium can be processed individually, in series, or in mass. The technological process is very similar in each case. The basic operation is the correct configuration of the CNC machine, the task of which is to perform the target movements in a number consistent with the number of required details.

In the entire process, computer software plays an important role. Compared to traditional machining, CNC milling largely automates part of the work. After appropriate programming, the machine independently performs the assigned activities according to a specific algorithm.

The operators’ tasks are limited to basic activities such as:

– tool mounting,

– selection of cutting parameters,

– positioning and mounting of the workpiece.

CNC milling machines ensure high precision of work, thanks to which the finished aluminum parts are fully compliant with the established specifications.

What are the applications of CNC milling of aluminum?

CNC milling of aluminum is a service with a very versatile purpose, which is also exceptionally economical. The price of processing with this method depends on several key factors. The cost of implementing a project is largely determined by its level of complexity, as well as the size of the entire order.

The dimensions and other parameters of the target parts are also important. At our company Karbo CNC you can count on a completely free quote, which guarantees optimal adjustment of the service to the client’s available budget.

Versatility and universality

The milling offered by our company allows for very precise processing of any pattern, and can also be done on many surfaces. We process various aluminum elements, including molds, parts and components used in many industries. We also successfully mill other materials, such as steel, brass, bronze or plastics.

We strictly adapt our services to the individual expectations of the client, regardless of the requirements in terms of specification. We take care of the highest quality of workmanship of every detail, including ensuring high precision and optimal dimensional tolerance. We constantly monitor all stages of work, which ensures that the desired parameters of the processed elements are maintained.

Comprehensive possibilities

Milling is currently used in many segments of industrial activity and not only. We use this method to prepare various spare parts for engines, cars, gearboxes and other components for the automotive industry. CNC technology also works great in pneumatics, especially in terms of preparing various tools, devices and other equipment.

Additionally, we perform various processing for:

– food plants,

– electronics segment,

– energy industry,

– pharmaceutical industry.

You can see Karbo CNC’s previous projects on our website. We encourage you to check out our current service offer, as well as to contact us and ask any questions regarding milling.

CNC milling of aluminum is a modern method of processing that combines high precision, repeatability and great versatility. Thanks to the use of CNC technology, it is possible to quickly and accurately shape details of varying degrees of complexity. Karbo CNC offers comprehensive services, including design, milling and quality control of finished products. We invite you to cooperate!

18.06.2025

18.06.2025