20.01.2025

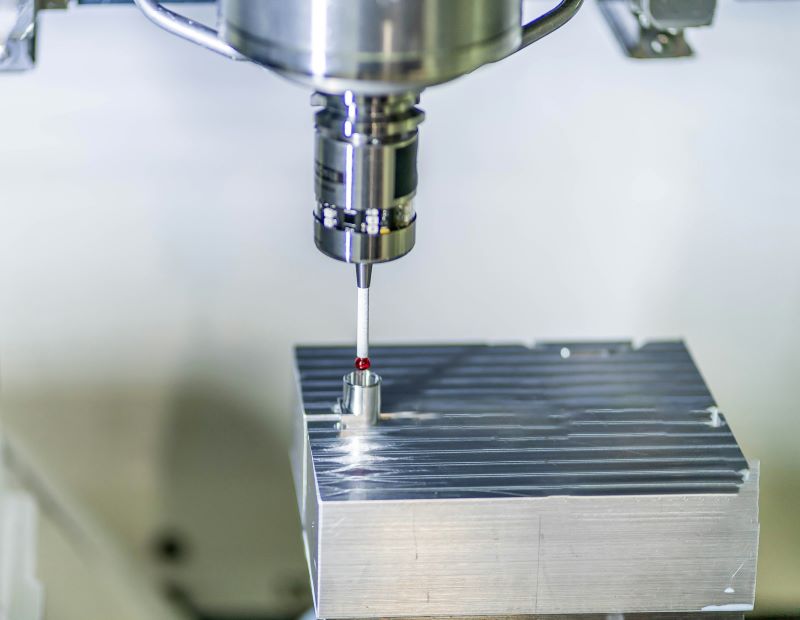

Boring is one of the commonly used machining methods, enabling precise improvement of the quality of an existing hole in a component or increasing its diameter by removing excess material. This process uses advanced tooling systems that guarantee the maintenance of the desired geometry and dimensional accuracy. This technique is perfect for the production of complex components requiring the highest manufacturing precision.

What is boring?

At Karbo CNC, we specialize in precision boring, using advanced numerically controlled machines. CNC technology ensures high repeatability and excellent precision, which directly translates into the quality of the final product. Thanks to computer control, we have full control over the movement of the tool relative to the processed detail, which allows for exceptionally precise machining.

Our methods enable effective shaping of holes of various geometry, achieving tolerances of up to H6. Thanks to this, we are able to meet the highest technical and quality requirements.

Modern manufacturing technologies

In our projects, we use modern numerically controlled machines, which are a significant step forward compared to traditional machining technologies. One of their key advantages is the possibility of automated tool handling, which ensures high precision and repeatability of processes.

CNC boring is performed using specialist software based on precisely selected functions and algorithms. The control program is then executed by the machine controller, and the entire process requires only minimal operator intervention. Thanks to this, the machining is not only more accurate, but also more effective and repeatable.

The advantages of our service include the possibility of quick and trouble-free configuration of the entire process, as well as its comprehensive automation. At Karbo CNC, we use advanced CNC lathes and milling machines. We also take care of a comprehensive approach to each task, including project development and implementation, up to final production.

Versatile application

Boring using numerically controlled machines allows for the processing of various materials, such as steel, aluminum, regular and non-ferrous metals, and even plastics. The key stage of the process is the proper preparation of the machine, which then performs a specified number of repetitions.

The part to be machined is clamped in a lathe if it has a rotating shape, or in a milling fixture if it is not a rotating part. A turning tool or a milling cutter precisely removes excess material, always in accordance with previously established parameters.

The computer control process is significantly different from traditional manual operation. Our CNC machines perform all operations according to programmed instructions, eliminating the need for manual tool setting or corrections during work. Thanks to this, we ensure high precision, repeatability and full compliance of finished elements with the customer’s requirements.

What are the benefits of professional boring?

Boring performed using our professional solutions provides many benefits. The service is dedicated to various applications, which is why it works great in many industries. At Karbo CNC, we can effectively match the technologies and solutions used to the individual needs of the customer. We also take care of the economic implementation of the work and offer a free quote. The costs of the service depend on the level of complexity of the project, the size of the order or the specificity of the material being processed. You can check sample implementations on our website.

High precision and excellent quality

At Karbo CNC, we pay special attention to precision and accuracy. We are able to process the elements submitted for processing on many levels, regardless of the specificity of the component or its form and dimensions. We take special care to specific parameters in order to maintain the desired material properties and the required technical specification. The key aspect of our processing is high final quality.

At Karbo CNC we use methods that always bring the right result. This is largely ensured by effective control and constant monitoring of all progress.

A comprehensive approach to machining

In our company, we always try to be up to date, which is why we closely follow all innovations in the CNC industry and implement new technological solutions. Our specialists have many years of experience and also ensure compliance with applicable standards, directives and regulations. All this translates not only into compliance with customer expectations, but also into high safety of the production process.

We have an advanced machine park, thanks to which we can efficiently fulfill orders for both large and small series. In our company, we also successfully perform other services. We offer, among others, milling, grinding, welding and locksmithing, as well as CAD design and 3D scanning and printing.

We encourage you to learn more about Karbo CNC services and contact us by phone or via the form on the website.

18.06.2025

18.06.2025