18.12.2024

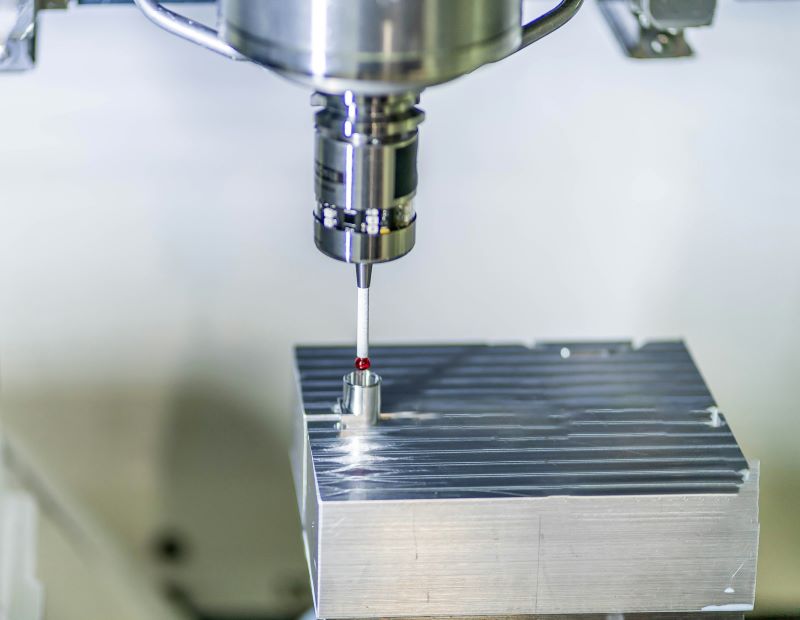

The processing of non-ferrous metals is widely used in various industries. Regardless of the type of metal being processed and the intended end results, it is an extremely precise process, so it requires a professional approach at each stage of work. Currently, thanks to the use of modern technologies, many processing activities are carried out automatically. Such activities include the processing of non-ferrous metals using CNC machines. This guarantees high precision and repeatability of manufactured details as well as exceptionally wide possibilities of shaping them in accordance with the guidelines provided by the client.

What are the characteristics of modern processing of non-ferrous metals?

Modern non-ferrous metal machining includes activities such as CNC milling, CNC turning, CNC drilling and tapping, CNC grinding and polishing, and cutting and cutting. The first three of the above-mentioned processes constitute the core of the activities of our company, Karbo CNC. It is also worth noting that all machining works offered by Karbo CNC, in particular CNC milling, turning, drilling and threading, are carried out in a way that meets the requirements and needs of customers from various industries. Starting from the automotive and aviation industries, through energy and electrical engineering, construction, as well as the chemical and pharmaceutical, medical, maritime, jewelry and machine construction industries. This involves processing various non-ferrous metals such as aluminum, brass, bronze, tin, copper and lead. Activities carried out by Karbo CNC also include 3D scanning, CAD/CAM design and welding services. We also process steel, stainless steel, sintered carbides, fiberglass and plastics. We encourage you to familiarize yourself with our full offer, and if you have any additional questions, our specialists will be happy to help.

Precision and repeatability

At Karbo CNC, we use advanced CNC machining technologies, which guarantee exceptional precision and full repeatability of parameters. Thanks to computer control, we minimize the risk of errors, which translates into the highest quality of finished products and components. We can prepare different variants of the same details, adapting the program settings to individual needs. Our services are not only precise, but also economical – we shorten production time and reduce material consumption. We also care about work safety, ensuring optimal conditions for processing non-ferrous metals.

Comprehensive application

Our services are used in many industries. We supply engine and car components for the automotive industry, as well as precise parts of machines, tools and devices for the industrial and pneumatic sectors. We also specialize in the processing of elements for the food industry, including butcheries and slaughterhouses, requiring comprehensive equipment. We also serve other sectors, such as agriculture, aviation, metallurgy, textile, wood, energy, electrical engineering, electronics, chemical and petrochemical industries.

Non-ferrous metals are extremely popular due to their susceptibility to precise processing and a wide range of applications. We invite you to check out our projects on the Karbo CNC website.

What are the benefits of professional processing of non-ferrous metals?

The processing of non-ferrous metals is carried out by our specialists mechanically and surface-wise, which requires appropriate experience. In our services, we use proven technological solutions and we approach each project creatively. At Karbo CNC, we always ensure timely and comprehensive service, which ensures efficient project development and obtaining final products of excellent quality. Due to our diverse machinery, we successfully adapt to our customers’ needs. We can carry out both small and larger production runs.

Efficient implementation

At Karbo CNC, we ensure precise configuration and optimal adjustment of all machines. Regardless of the complexity of the detail or the specificity of processing, we carry out each work in accordance with the guidelines and technical specifications provided by the client. Our advanced machines precisely give non-ferrous metals the required shapes and forms, using appropriate movements and actions of processing tools. Thanks to a carefully planned processing process, the final effect always meets the assumptions of the original technical specification

Professional and comprehensive service

We offer a wide range of processing techniques, which allows us to tailor each service to individual customer requirements. Thanks to modern machines, we guarantee exceptional precision and speed of order execution, which translates into significant optimization of production processes.

We provide professional support and advice at every stage of cooperation. Regardless of the specific nature of the order, we always give priority to the accuracy of workmanship and the full satisfaction of our customers. Using modern technologies, we ensure precise dimensional tolerance and meet all technical requirements.

Please contact our experts and check out the Karbo CNC offer!

18.06.2025

18.06.2025