19.09.2024

Aluminum welding is a popular method of joining elements made of this material. The methods currently used are very precise, which guarantees unique aesthetics of the connections and their high durability. Aluminum is welded for the needs of many industries. However, for this type of services to bring the desired results, they should be performed by qualified experts. The basis for successful service implementation is the selection of appropriate techniques and tools.

What is aluminum welding using MIG, MAG and TIG methods?

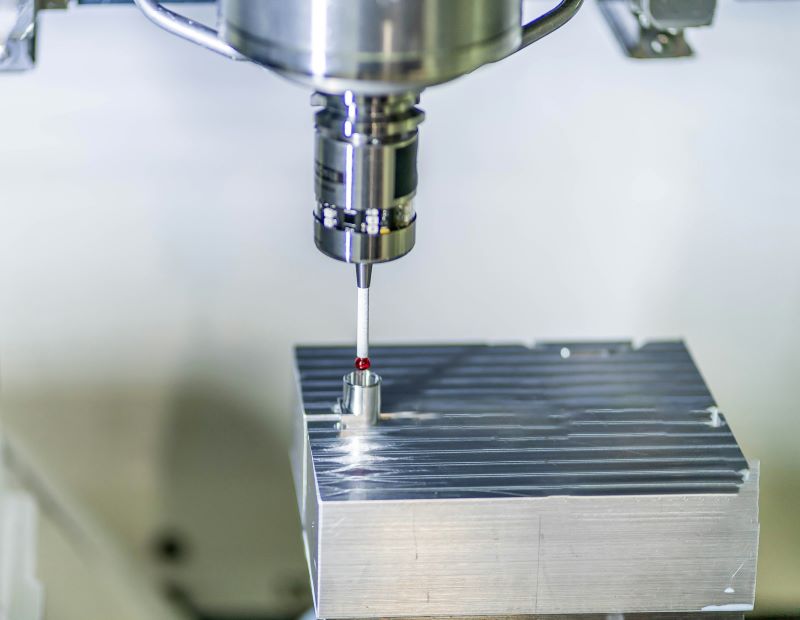

Aluminum welding can be carried out using various solutions, and currently the most common methods are TIG, MIG and MAG. We use such technologies in our company Karbo CNC, where we guarantee the highest quality of each service. We are currently one of the leaders in the industry, which we have achieved thanks to our excellent knowledge of the market and investor requirements. Our specialists also successfully provide other services, especially in the field of CNC machining. We deal with, among others: turning, milling and grinding, as well as developing CAD designs and performing three-dimensional scanning for many applications.

MIG and MAG techniques

MIG and MAG techniques involve the use of a special electric arc that is generated between the consumable electrode and the welded element. In the wire feeding process, it is necessary to use an appropriate shielding gas. In the MIG method, the shielding gas is chemically inert (e.g. argon or helium), while in the case of the MAG technique, a chemically active gas (e.g. carbon dioxide) is used. Both of these solutions are perfect for joining aluminum and its alloys, as well as low-carbon, stainless, acid-resistant or alloy steels, copper and other non-ferrous metals. Today, both methods are used in most projects requiring arc welding.

TIG technique

The TIG method is also based on the use of an electric arc, but the main difference is that the arc is produced using a non-fusible tungsten electrode in an inert gas coating. The welding process allows aluminum components to be fused directly or by adding additional melting material to the weld pool. The TIG technique allows you to obtain a high-quality weld, free from any contamination. This method is perfect when you need to use a neutral protective gas. TIG welders are perfect for small-thickness aluminum elements whose welds must be aesthetic and durable, e.g. thin-walled pipes or sheet metal.

Why should aluminum welding be performed by experienced professionals?

Aluminum welding is a specific and demanding process, so it is worth entrusting this type of services to qualified experts. At Karbo CNC, we implement various projects in this area, regardless of their size and type. We approach each task with great commitment, we have the necessary skills and many years of experience. We approach service responsibly, ensuring punctuality, and we are willing to undertake difficult projects that require creativity. As our client, you can be sure that the entire service will be properly planned and performed efficiently.

Specialized service

The welding processing methods used by our specialists are very modern, thanks to which they allow the implementation of each service in accordance with customer guidelines and applicable industry standards. We have an extensive machinery park, consisting of devices that guarantee the highest quality of all machining. Cooperation with Karbo CNC can significantly speed up and improve the production process of various elements, components and aluminum details. We provide comprehensive and specialized service, which contributes to a very careful and individual approach to implementation. We treat each project individually, selecting the solutions that are most beneficial for the final result.

High-quality processing

Karbo CNC ensures the highest quality of each welding process, as evidenced by the satisfaction of our customers. We rely on reliable and proven technologies, and we constantly introduce new solutions to our offer. Each element welded by our experts has excellent parameters that fully meet all the requirements for the final technical specification. We constantly supervise and control the course of work, which affects the final bonding effect and the safety of our activities. We invite you to familiarize yourself with the offer of Karbo CNC services and establish cooperation, and please contact us if you have any questions.

18.06.2025

18.06.2025