3D printing is an innovative production technology that allows you to create fully three-dimensional objects based on a previously prepared digital model. Our service significantly expands the standard production capabilities of enterprises because it contributes to improving the efficiency of manufacturing many components. Three-dimensional printing increases control over individual stages of the process and at the same time improves the quality and functionality of the final products.

3D printing is one of the services we provide at our company Karbo CNC. For this purpose, we use advanced technologies and solutions that ensure high efficiency of component production and reduce production costs.

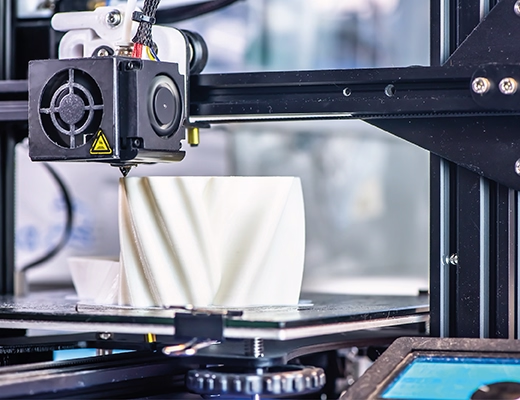

This service is largely based on computer-aided CAD design, as well as the use of modern 3D scanners, printers and CNC machines. The 3D printing process is particularly appreciated in the form of additive manufacturing, which involves the production of objects by successively applying subsequent layers of material.

3D printing at Karbo CNC is a specialized service that we provide with the utmost attention to compliance with the planned technical specifications of the target elements.

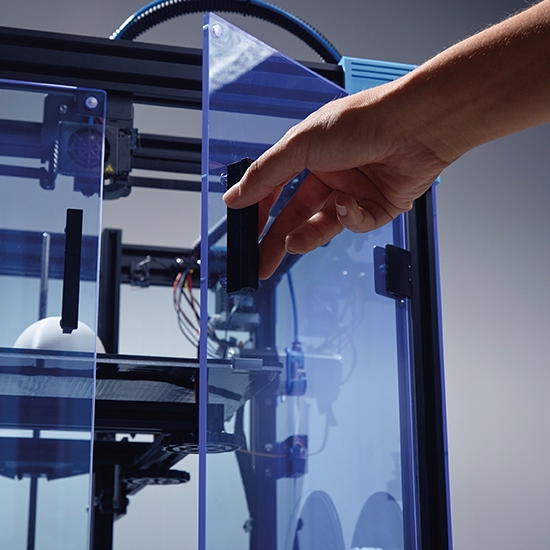

Our experts have the necessary qualifications and use modern and certified equipment.

We ensure compliance with applicable standards in terms of precision and accuracy of 3D printing, while acting on the basis of current standards.

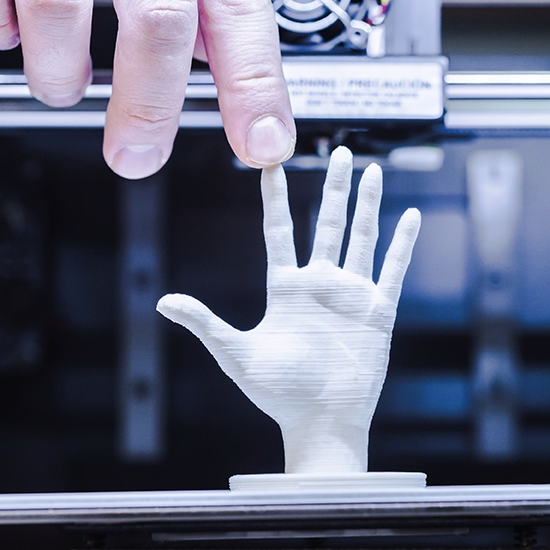

We print both basic elements and large components with a certain degree of complexity in terms of geometry. We also offer access to complete documentation.

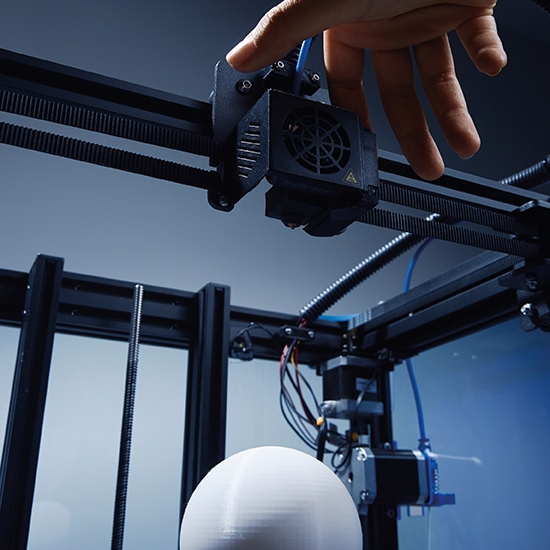

This technology requires the use of specialized equipment, which we have at Karbo CNC. The basis is 3D modeling software, which is a properly functional application. Modern 3D printers are used in production processes, which enable additive manufacturing for various projects.

Another necessary element is a container of raw materials intended for printing components, and metal and plastics are most often used for this purpose. The first stage involves developing a 3D model of the planned product, which is handled by the workstation software. The file obtained in this way describes individual layers, which enables its effective use by a 3D printer. Next, serial printing takes place in a specified number, after which the finished components come off the production line and are adapted for further CNC processing or final operation.

Evaluate customer requirements, select appropriate processing methods and technologies, and develop a work plan.

Creation of technical and process documentation, and preparation of appropriate tools and selection of machinery.

Execution of the planned technological process, according to the guidelines and documentation.

Conduct quality control, based on the established quality assurance system.

Due to advanced technical equipment and extensive machinery, we are able to undertake many demanding tasks related to 3D printing. At Karbo CNC, we use modern methods that are optimally suited to customer requirements.

The high functionality of the equipment allows us to carry out 3D prints for the needs of numerous business segments. We have a comprehensive offer that also focuses on other engineering activities and processes – including grinding, milling, turning, welding and other CNC machining. We take a professional approach to each project, which translates into comprehensive service and a guarantee of satisfaction.

At Karbo CNC, we ensure the highest quality of each 3D printing, which results from the use of top-class devices and the competence of our specialists. We use proven materials and technologies, and integrate numerous improvements and innovations in our projects.

We constantly monitor the market and educate our staff to ensure professional and satisfactory service. We carefully control each stage of printing work, ensuring safety and the highest production quality. We encourage you to check the Karbo CNC service offer, and we invite you to contact our specialists and establish cooperation.