13.04.2024

Machining is currently one of the most popular methods of processing and shaping various materials, especially metal. Currently, this process can be performed automatically thanks to the use of modern CNC machines. This solution is based on special algorithms that guarantee the implementation of the project in accordance with the guidelines. Machining with this method ensures high repeatability and precision, which is important in many industries.

What is precision machining of stainless steel, aluminum and other metals?

Precise machining of stainless steel, aluminum and other metals is the basis of the offer of our company Karbo CNC, where we efficiently carry out the entire process. First, we develop a CAD/CAM design and configure machines to then carry out machining activities and obtain the final product. During our work, we use technologically advanced devices as well as specialized tools for shaping individual materials. In this way, we obtain details that comply with the guidelines in terms of required dimensions, properties, forms and other parameters.

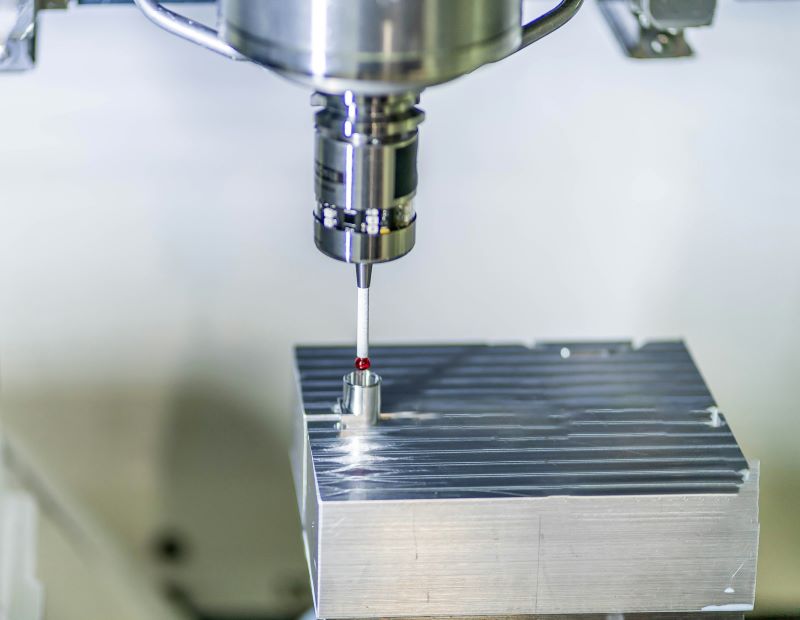

Appropriate design

The basis for shaping metals using this method is an appropriate CAD/CAM project, which we prepare using dedicated software. Element models can thus be created based on specific technical parameters, such as exact dimensions or geometric form. The only limitation in the design process is the actual capabilities of CNC machines, as well as the properties of the processed material. We also have to take into account the parameters of the available equipment, e.g. permissible part thickness and maximum dimensions. Finally, the finished project is exported to a compatible format that allows the data to be read by the algorithms responsible for subsequent CNC machining.

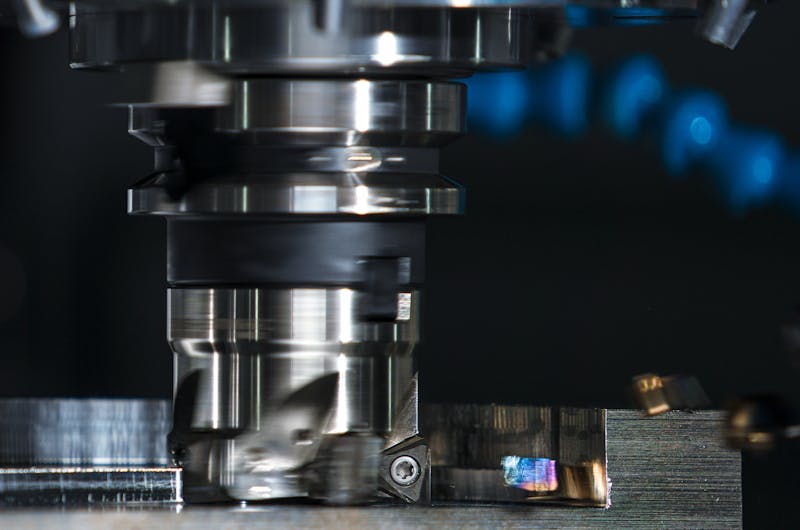

Machine configuration and machining process

Machines for carrying out the work must be properly prepared for the project. The processed detail is fastened using special fastening elements. At the next stage, we define the position of the workpiece in the working chamber of the machine. Once the machine tool is set up, we run the CNC program with the required instructions. Based on it, the machine performs specific movements and other operations that enable material processing. Thanks to highly developed technology, we can successfully carry out complex simultaneous machining defining unusual shapes on the processed detail.

What are the benefits of machining through turning, milling, grinding and other services?

Machining can include very diverse services, such as turning, milling or grinding. At Karbo CNC, we ensure efficient operation of the entire process that allows you to perform these operations. We also specialize in 3D scanning and welding services. We approach the needs of each investor comprehensively and individually, and we also ensure the optimal selection of technological solutions. We provide professional service and are happy to undertake unusual, demanding machining projects.

High precision and efficiency

Processing with this method ensures efficient processing of various materials, while guaranteeing high precision and repeatability of details with the required characteristics. CNC technology significantly reduces the likelihood of manufacturing errors, which has a beneficial effect on the final quality of products. The processing carried out by our experts allows for the production of many variants of each component, which is done by quickly modifying the program and changing parameters. CNC is also an extremely profitable and economical method due to reduced operating costs and shortened production time. Another advantage is high processing safety, because the automation of many stages reduces the risk of accidents involving the operator during work.

Wide application possibilities

We perform this type of work for various areas of activity, including the automotive, medical, pneumatic, aviation, energy, electrical, pharmaceutical, catering, agricultural and many other segments. For the needs of such industries, we use modern machinery and specialized cutting tools, which allows us to shape elements of any shape.

Please contact us by e-mail or phone to discuss the project in detail and learn more about Karbo CNC services.

18.06.2025

18.06.2025