11.06.2025

Metal machining is an exceptionally precise processing method that finds applications in numerous industries and beyond. Currently, the implementation of this type of service has been significantly improved thanks to its reliance on innovative technologies. One such technology is the use of numerically controlled (CNC) machines. Such machining allows for the rapid, automated, and repeatable shaping of components and details, which is crucial for many projects.

What does metal machining involve?

Metal machining is a specialty of our company, Karbo CNC, where we provide comprehensive services to our clients. We can develop the necessary design and prepare materials, as well as configure and operate CNC machines. Our machining services primarily include milling, turning, and grinding. We machine parts from a variety of materials, including steel, aluminum, and stainless steel. We ensure compliance with standards, error-free operation, and a smooth production process, ensuring the parts we produce have optimal dimensions, properties, and other parameters.

Design and Preparation Stage

Machining cannot begin without proper preparation. This stage forms the basis for a proper CAD/CAM design, implemented using specialized software. This creates a model with specific technical parameters, allowing for a faithful reproduction of the required dimensions and geometric form. This design must be prepared in accordance with the properties of the metal being processed, as well as the specifications of the CNC machine itself – including permissible dimensions and thickness. Finally, the finished design is exported to a compatible format so that the machining algorithms can correctly interpret it. The design stage also includes analyzing technical documentation and selecting tools, and preparing the CNC machines – their configuration, material clamping, and setting cutting parameters.

Machine Setup and Production

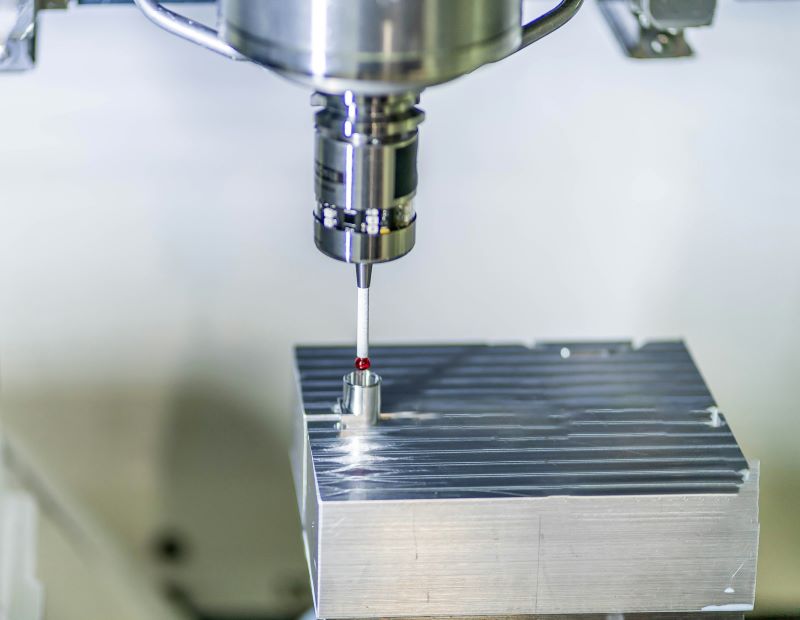

CNC machines responsible for machining require proper setup. The metal part to be cut must first be clamped in vises or spindles, which act as holders. The next step is to configure the tooling itself. Once the CNC machine is properly set up, the actual production process begins. The program runs according to the assigned instructions, ensuring that cutting always proceeds according to the required movements. Metal processing using this method requires proper control to eliminate the risk of errors or loss of compliance with design guidelines. We continuously monitor the machining process, ensuring the highest quality of parts.

What benefits can CNC metal machining provide?

CNC metal machining offered by our specialists focuses on various services with very versatile applications. At Karbo CNC, we provide professional service to our clients, regardless of the specifics and scope of the order. Our offer also includes other services, including 3D scanning and printing, and welding services. We successfully meet all customer guidelines and requirements, ensuring the skillful selection of the best technological solutions. We are able to complete even the most non-standard and complex CNC machining orders. Our services are characterized by high precision, repeatability, speed of execution, and process safety.

High precision and efficiency

CNC technology allows for highly precise and accurate cutting of various metal materials, including stainless steel and aluminum. The advantage of this approach is its high repeatability, ensuring that finished parts have identical parameters and physical properties. The use of numerically controlled machines also reduces the risk of manufacturing errors, resulting in a very high-quality finished project. As part of our services, we can also provide different variants of the same product, modifying the design based on current needs. CNC is also a very cost-effective and economical solution, thanks to the limited scope of work and rapid completion. All work is performed in safe conditions, and limited contact with the machines significantly minimizes the likelihood of accidents. We also ensure cost-effective execution thanks to shorter processing times and individual pricing for each project.

Versatility and Universality

One of the advantages of our machining services is their high versatility. CNC machines are highly versatile, making them suitable for the production of parts for industries such as automotive, pneumatics, agriculture, pharmaceuticals, electrical, and energy. This wide range of applications stems from the high efficiency of the cutting tools themselves. Our company is equipped with modern CNC milling machines and lathes, which are ideal for machining metal parts with diverse operational requirements. We also serve the aerospace industry and implement both individual and series projects. If you have any questions, please contact our experts. We also invite you to review Karbo CNC’s previous projects and explore other services available, such as comprehensive metalworking. We offer free quotes and technology consultations.

18.06.2025

18.06.2025